In today's rapidly evolving electronics landscape, the demand for fast PCB manufacturing has surged, driven by the increasing need for swift product development cycles and the growing complexity of electronic devices. According to industry reports, the global PCB market is projected to reach $100 billion by 2025, with a significant portion attributed to the quick turnaround of prototypes and low-volume production. As global buyers seek innovative alternatives to traditional manufacturing methods, it's essential to explore various strategies and technologies that can streamline processes, enhance efficiency, and reduce costs.

This blog delves into unique alternatives in fast PCB manufacturing, illuminating how these approaches can empower manufacturers and buyers alike to stay competitive in a fast-paced market.

The global demand for fast PCB manufacturing is on the rise, driven by the rapid growth of electronic devices and increasing IoT applications. The printed circuit board market, projected to grow from $71.57 billion in 2024 to an impressive $113.49 billion by 2028, highlights the urgency for manufacturers to adapt quickly to evolving customer needs. India is emerging as a key player in this landscape, attracting international organizations with its promising opportunities for electronics manufacturing. With the country's electronics sector expected to reach $300 billion by 2025-26, it presents a sustainable manufacturing hub for global buyers seeking fast PCB solutions.

The global demand for fast PCB manufacturing is on the rise, driven by the rapid growth of electronic devices and increasing IoT applications. The printed circuit board market, projected to grow from $71.57 billion in 2024 to an impressive $113.49 billion by 2028, highlights the urgency for manufacturers to adapt quickly to evolving customer needs. India is emerging as a key player in this landscape, attracting international organizations with its promising opportunities for electronics manufacturing. With the country's electronics sector expected to reach $300 billion by 2025-26, it presents a sustainable manufacturing hub for global buyers seeking fast PCB solutions.

Tips: When looking for fast PCB manufacturing partners, consider their production capacity and lead times. Engaging with manufacturers that utilize advanced technologies can significantly enhance speed and efficiency. Additionally, understanding the local market dynamics in regions like India can provide valuable insights into supply chain optimization and cost-effectiveness.

As manufacturers strive to meet the heightened demand, leveraging deep learning and machine learning techniques can lead to improved supply chain management. These technologies not only enhance production and inventory control but also streamline supplier selection processes, making it imperative for companies to invest in innovative solutions to stay competitive in the fast-paced PCB industry.

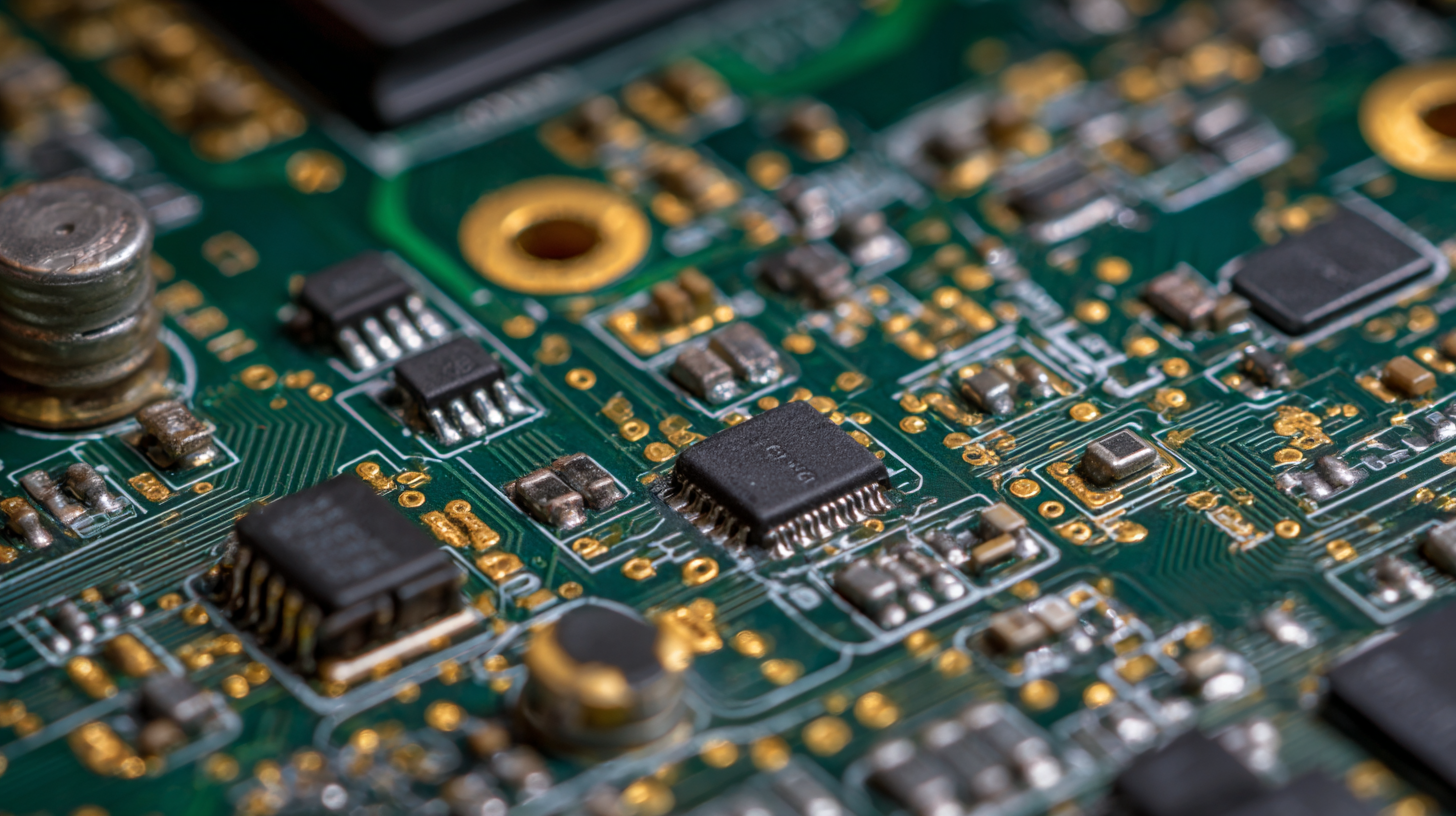

In today’s fast-paced electronics market, global buyers are increasingly seeking unique alternatives in PCB manufacturing that stand out from traditional options. One of the key characteristics of these unique alternatives is flexibility in production capabilities. Modern suppliers are increasingly adopting advanced technologies such as additive manufacturing and flexible PCB designs, which allow for the creation of intricate geometries and multi-layer boards, catering to specific client needs. This not only enhances the performance of the end product but also reduces time-to-market for innovative electronics.

Another important aspect of unique alternatives in PCB production is sustainability. Many manufacturers are now focusing on environmentally friendly materials and processes, minimizing waste and energy consumption. This shift not only helps in compliance with global regulations but also appeals to eco-conscious consumers and companies looking to reduce their carbon footprint. Additionally, incorporating green practices often leads to enhanced reliability and longevity of the PCBs, contributing to overall customer satisfaction and loyalty in a competitive marketplace.

| Alternative Production Method | Key Advantages | Lead Time | Cost Efficiency | Applications |

|---|---|---|---|---|

| Additive Manufacturing | Reduced material waste, complex geometries | 3-5 days | High initial cost but lower long-term costs | Prototyping, low-volume runs |

| Flexible PCBs | Lightweight, adaptable to various shapes | 7-10 days | Moderate, depending on complexity | Wearable tech, compact devices |

| Rapid Prototyping | Fast iteration, quick time to market | 2-4 days | Generally cost-effective for small batches | Initial design exploration, testing |

| High-Density Interconnect (HDI) | Compact design, better performance | 10-15 days | Higher upfront cost but savings on space | Smartphones, complex electronic devices |

| RFID Embedded PCB | Integration of RFID technology, space saving | 15-20 days | Varies; generally economical for mass production | Inventory management, access control |

In the competitive world of electronics, the speed of production often dictates market success. As global buyers seek faster solutions for printed circuit board (PCB) manufacturing, evaluating the cost-effectiveness of various fast PCB options becomes crucial. Companies are increasingly recognizing that the cheapest option may not always be the best choice, especially when considering quality, reliability, and delivery times.

Fast PCB manufacturing alternatives, such as local fabrication facilities and specialized online services, offer diverse pricing structures. While traditional manufacturers might charge a premium for expedited services, emerging services that utilize advanced technologies can provide quicker turnaround at a fraction of the cost. Additionally, some manufacturers offer tiered pricing based on complexity, allowing buyers to optimize their expenditures depending on project requirements. By meticulously comparing these options, buyers can make informed decisions that align with both their timelines and budgets, ensuring that they remain competitive without sacrificing quality.

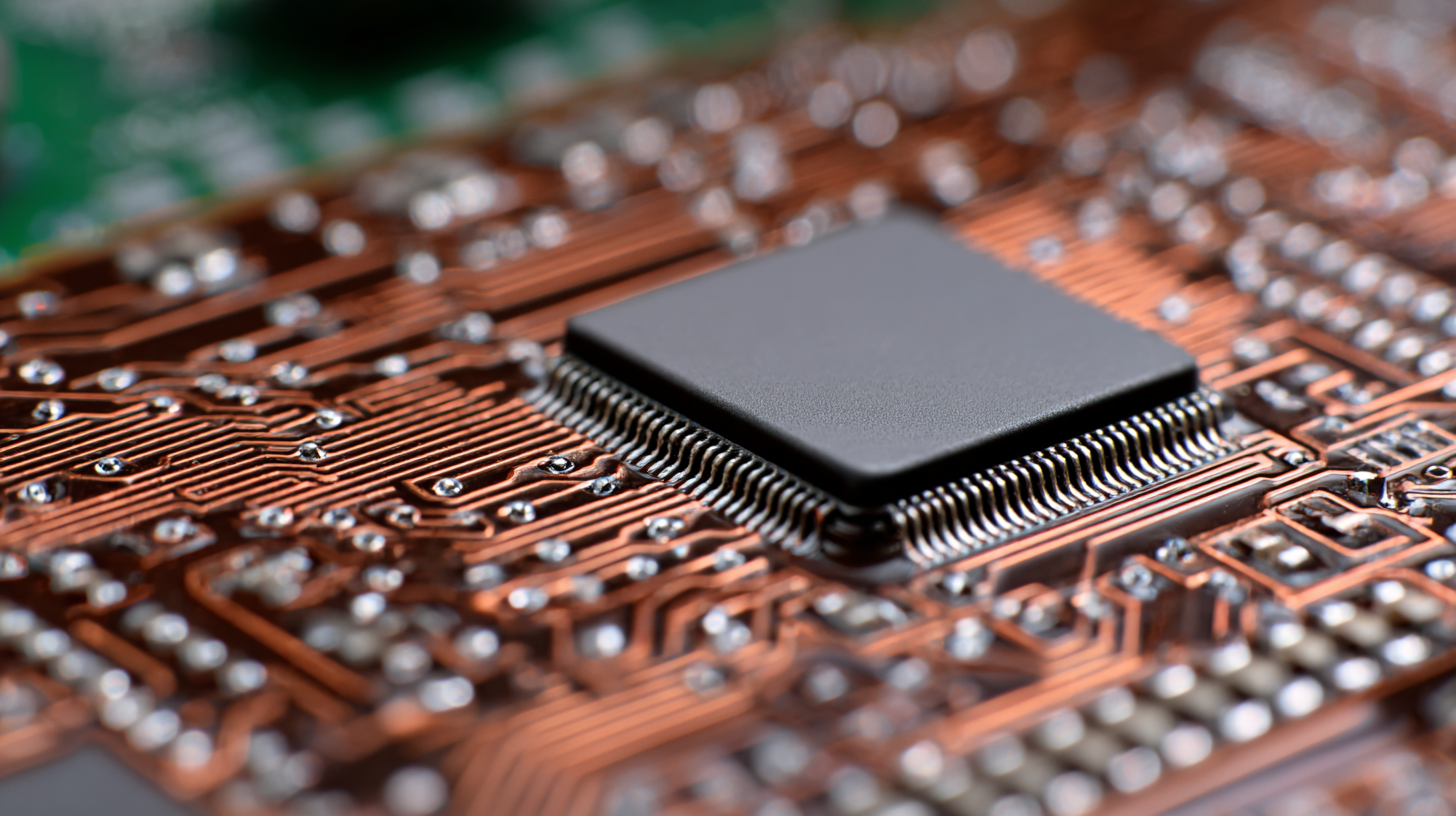

In the fast-paced world of electronics, the demand for rapid PCB manufacturing is growing, leading to an increased focus on innovative technologies that enhance efficiency. The global PCB market is projected to reach approximately $90 billion by 2027, driven by advancements in manufacturing techniques and the relentless pursuit of faster production times. Integrating innovations such as automated surface mounting technology (SMT) and artificial intelligence in design processes can substantially streamline fabrication workflows, reducing lead times by up to 40%.

To optimize your PCB manufacturing process, consider implementing advanced CAD software that supports real-time collaboration among design teams. This can minimize errors and promote quicker revisions, ultimately leading to a more seamless production pipeline.

Another crucial tip is to prioritize suppliers that utilize high-quality materials combined with innovative manufacturing techniques, like additive manufacturing and laser processing. These approaches not only enhance product reliability but also allow for more complex designs, catering to the diverse needs of global buyers. By staying informed on industry trends, companies can maintain a competitive edge in the dynamic PCB landscape.

Navigating supplier relationships is crucial for international PCB sourcing, especially as global demand continues to rise. When exploring diverse options for fast PCB manufacturing, buyers must focus on establishing strong, transparent connections with suppliers. This not only ensures a smoother procurement process but also fosters trust, which is essential in dynamic markets. Understanding each supplier's capabilities and limitations allows buyers to make informed decisions that align with their operational needs.

Building effective communication strategies is another vital aspect of these relationships. Regular updates about production timelines, quality control measures, and specific project requirements can mitigate misunderstandings and enhance collaboration. Moreover, leveraging technology for real-time communication and project management tools can streamline interactions, making it easier for global buyers to manage multiple suppliers across different time zones. By prioritizing these elements, companies can optimize their PCB sourcing processes, ultimately resulting in higher quality products delivered in a timely manner.