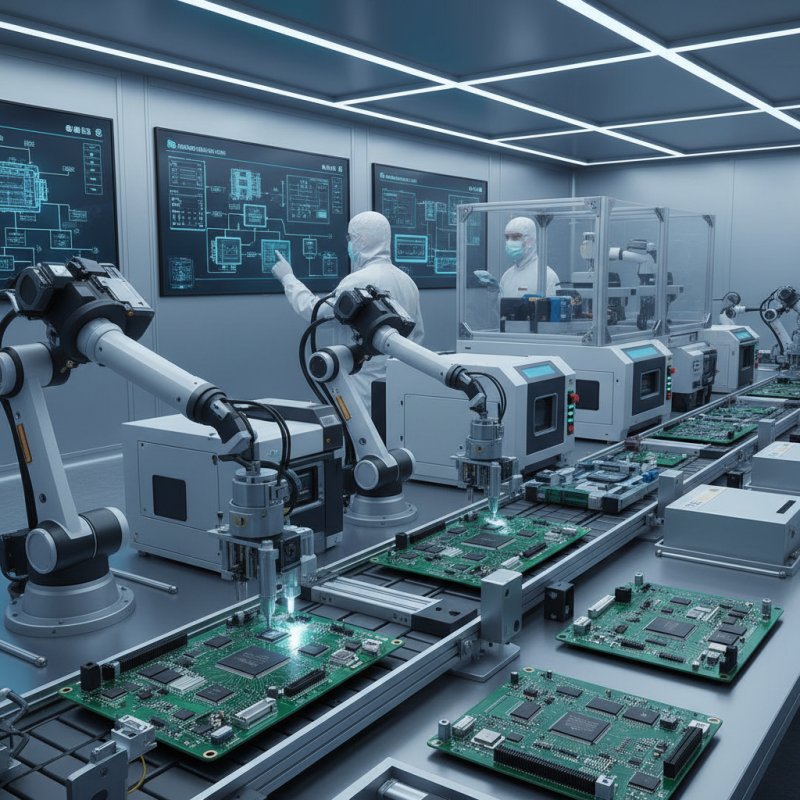

In the fast-paced world of electronics, efficient PCB manufacturing and assembly are crucial. The process impacts both performance and cost. Many companies face challenges in optimizing these operations. Streamlining production can lead to shorter lead times and reduced waste. However, achieving this requires more than just technology; it demands a strategic approach.

Consider the complexities involved. Each PCB design is unique and varies in requirements. This leads to potential pitfalls in sourcing materials or managing timelines. It's important to reflect on past mistakes to improve future processes. For instance, overestimating production capabilities can cause delays and budget overruns.

Implementing best practices can significantly enhance efficiency. Our top 10 tips will guide you through the essential steps. From design considerations to quality assurance, these insights aim to bolster your PCB manufacturing and assembly efforts. Focusing on details can make a big difference. Ultimately, success lies in continuous improvement and adaptability.

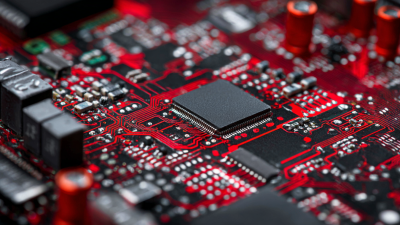

The PCB design process is crucial for efficient manufacturing. A well-structured design leads to fewer errors and reduced production costs. Studies show that poor design can increase manufacturing time by 30%, resulting in higher expenses. Understanding the intricacies of PCB design minimizes these risks.

Start with a clear schematic. This is essential for error-free assembly. Utilize simulation tools to predict performance before actual manufacturing. Prototyping can reveal potential pitfalls early in the process. It’s often said that a well-tested design saves days in production.

Considerations such as material selection and layer stack-up are vital too. They directly affect manufacturability. Thin traces and small holes, while trendy, can complicate assembly. A balance between design goals and production capabilities is key.

Lastly, effective communication with manufacturing partners can prevent misunderstandings. Sharing detailed specifications is vital. Miscommunication often leads to costly mistakes, wasting both time and resources. Engaging with manufacturers early can streamline the entire process.

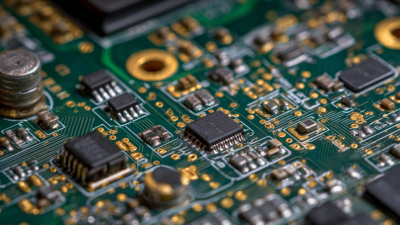

Choosing the right materials for PCB production is crucial for efficiency and performance. A recent survey indicated that about 70% of PCB manufacturers reported material choice as a key factor affecting production timelines. High-quality materials can reduce assembly defects and improve reliability.

When selecting materials, consider functional requirements. For instance, FR-4 is widely used due to its excellent electrical insulation properties. In contrast, high-frequency applications may require PTFE materials for better performance. It’s vital to match your materials to the specific application.

Tip: Always source materials from reputable suppliers. This reduces the risk of using subpar components. Poor quality materials can lead to manufacturing delays and higher rejection rates. A report by IPC shows that nearly 30% of defects stem from inadequate material selection. Rethink your choices carefully. Remember, the impact of your material decisions will ripple through the entire manufacturing process.

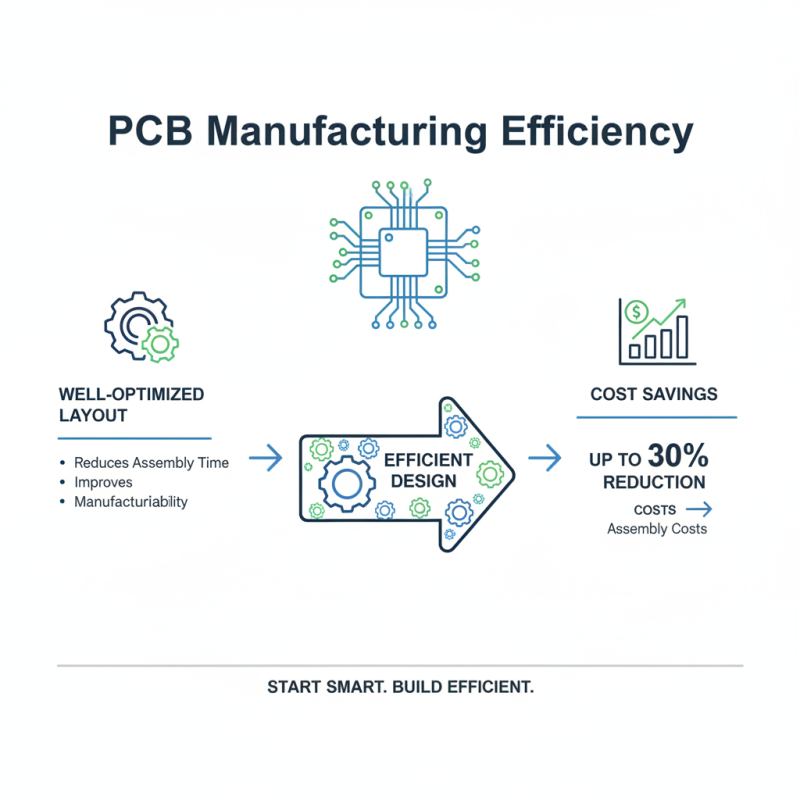

Efficient PCB manufacturing begins with a well-optimized layout. A well-thought-out design can reduce assembly time significantly. Industry studies suggest that improving layout efficiency can cut assembly costs by up to 30%. This highlights the importance of design in the manufacturing process.

One tip is to minimize the use of vias. Excessive vias can complicate assembly and increase costs. Aim for a design that seamlessly integrates components. Fewer vias lead to shorter traces and can enhance signal quality. It’s essential to keep component placement logical. Group similar components together to streamline soldering processes.

Another point to reflect on is the balance between complexity and functionality. While advanced features might seem attractive, they can hinder assembly efficiency. If a design is too complex, it may lead to higher error rates during assembly. Striking a balance is crucial. Empirical data indicates that simpler designs often lead to more reliable products. Keeping this in mind during the layout phase can save time and resources in the long run.

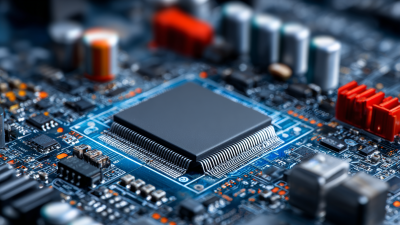

Effective testing protocols in PCB manufacturing are crucial for ensuring high-quality products. A well-defined testing strategy can reduce errors. Implementing automated testing can streamline the process. However, relying solely on automation can lead to oversight. Manual checks are essential for anomalies that machines might miss.

Integrated electrical testing is a vital component. It identifies faults early in the production cycle. Testing methodologies must evolve with technology. Not every test is necessary for every board. Choosing the right method saves time and resources. Sometimes, teams may forget to analyze test data thoroughly. This oversight can result in repeated mistakes.

Creating a feedback loop is critical. Engineers should review data from tests regularly. This practice fosters continuous improvement. Establishing a culture of open dialogue helps teams reflect. It encourages shared responsibility for quality. Regular training on testing techniques is beneficial, yet it's often overlooked. Without ongoing education, skills become obsolete.

Effective communication between design and production teams is crucial for efficient PCB manufacturing and assembly. In many organizations, poor communication leads to mistakes and delays. A report from the IPC highlights that around 70% of production issues stem from miscommunication. This statistic underlines the necessity of establishing clear lines of communication from the start.

Regular meetings can make a significant difference. Design and production teams should meet weekly to discuss ongoing projects. This frequency allows for quick adjustments and shared insights. Consider using visual aids in these meetings. Flowcharts or prototypes can clarify complex issues. However, not all teams utilize this method, leading to persistent misunderstandings. It’s common to see projects stall due to unclear specifications.

Implementing collaborative software tools can streamline communication. These platforms provide a centralized location for all information. However, not every team adopts these effectively. Some personnel may resist new technology. According to a survey, only 55% of manufacturing teams utilize collaboration tools fully. Continuous training and encouragement are vital. Addressing resistance to change is necessary to enhance overall efficiency in PCB production.

| Tip Number | Tip Description | Benefits | Implementation Steps |

|---|---|---|---|

| 1 | Utilize Advanced CAD Tools | Improved accuracy and faster design cycle | Train team on new software features |

| 2 | Regular Design Reviews | Catch issues early, reducing rework | Schedule bi-weekly design meetings |

| 3 | Create Clear Documentation | Streamlines manufacturing and assembly | Develop standard templates for all projects |

| 4 | Foster Interdepartmental Collaboration | Enhances communication and reduces delays | Organize cross-functional team workshops |

| 5 | Implement DFM and DFA Principles | Reduces manufacturing and assembly costs | Review designs for manufacturability |

| 6 | Select Quality Materials | Increases reliability and reduces failures | Source materials from trusted suppliers |

| 7 | Use Prototyping Techniques | Validates designs before full-scale production | Employ rapid prototyping methods |

| 8 | Automate Repetitive Processes | Increases efficiency and reduces human error | Invest in automation technology |

| 9 | Conduct Regular Training | Keeps team updated on best practices | Schedule periodic training sessions |

| 10 | Leverage Feedback Loops | Enhances continuous improvement in processes | Implement a structured feedback system |