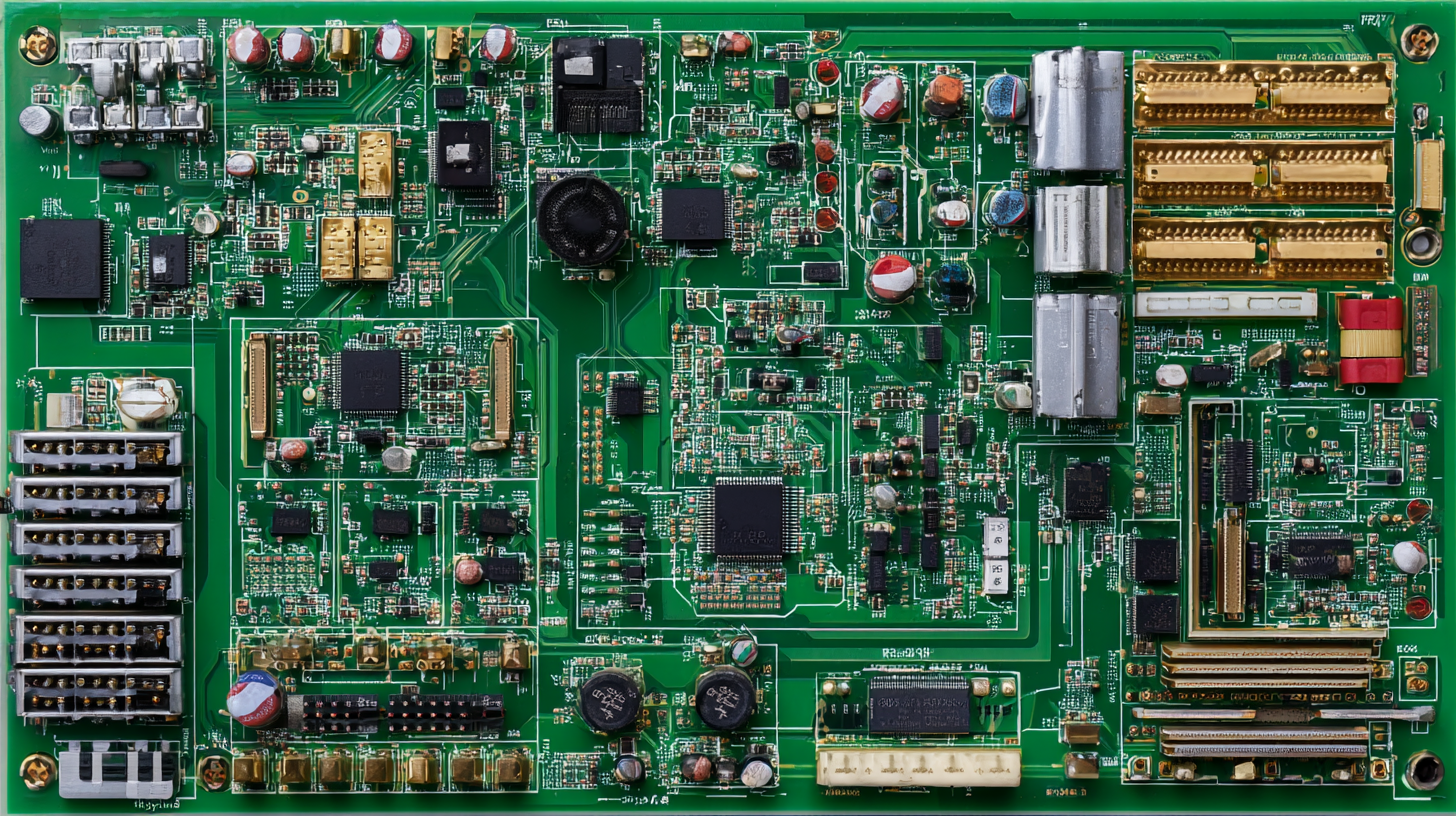

The importance of after-sales support in the electronics industry cannot be overstated, especially when it comes to maximizing the longevity and efficiency of printed circuit boards (PCB boards). According to a report by the International Data Corporation (IDC), companies that invest in robust after-sales services can reduce repair costs by as much as 30%, significantly enhancing customer satisfaction and loyalty. Moreover, as the global PCB market is projected to reach USD 84.19 billion by 2027, the need for effective maintenance and support to mitigate repair expenses becomes increasingly critical. Implementing strategic after-sales strategies not only helps in minimizing downtime associated with faulty PCB boards but also enables manufacturers to gather valuable feedback for continuous improvement.

This blog will explore various tips and best practices to leverage after-sales support effectively, ultimately assisting businesses in reducing repair costs and maximizing the performance of their PCB boards.

Enhancing after-sales support in PCB manufacturing is crucial for minimizing repair costs and ensuring customer satisfaction.

One effective strategy is to implement a comprehensive training program for support staff. By equipping them with the latest knowledge about product functionality and common issues, manufacturers can enhance their ability to troubleshoot problems effectively. This proactive approach not only helps in resolving customer inquiries quickly but also builds trust and loyalty among clients.

Another essential strategy is the development of robust communication channels with customers. Establishing multiple touchpoints, such as dedicated support lines, chat support, and online resources, allows clients to reach out easily whenever a problem arises. Regular follow-ups after a sale can also provide valuable feedback on product performance and customer experiences. This insight can guide future product improvements and after-sales services, ultimately leading to reduced repair costs and increased customer retention. By prioritizing efficient and responsive after-sales support, PCB manufacturers can create a competitive edge in the market while ensuring long-term success.

Understanding Customer feedback is pivotal for enhancing after-sales services in the PCB industry. According to a report from the IPC Association Connecting Electronics Industries, nearly 60% of customers who received prompt responses to their feedback expressed higher levels of satisfaction with the product and the support services. This highlights the need for PCB manufacturers to prioritize customer communication, ensuring that concerns regarding product performance are addressed swiftly.

Moreover, a study by Deloitte indicates that companies that actively seek and implement customer feedback can reduce their operational costs by up to 25%. By leveraging insights from customer experiences, manufacturers can identify common issues leading to repairs and design modifications that improve product reliability. This proactive approach not only enhances customer satisfaction but also minimizes repair costs, ultimately leading to a stronger brand reputation in a highly competitive market.

Engaging with customers post-purchase fosters loyalty and allows companies to stay ahead in delivering high-quality PCB boards.

Cost-effective solutions for minimizing repair costs in PCB boards have become increasingly vital as the electronics industry continues to evolve. According to a recent report by the IPC (Association Connecting Electronics Industries), nearly 30% of PCB manufacturing costs can be attributed to repairs and reworks. This highlights the importance of optimizing after-sales support to address issues swiftly, ultimately reducing overall expenses.

Implementing robust after-sales support mechanisms, such as online troubleshooting guides and 24/7 customer service, can significantly decrease repair times. A study by Technavio suggests that companies with effective support systems can cut repair-related costs by up to 15%. Additionally, leveraging predictive maintenance technologies can prevent failures before they occur, providing an even more proactive approach to managing costs. By focusing on these areas, companies can not only enhance their service offerings but also ensure the longevity and reliability of their PCB boards, aligning with the growing demand for high-quality electronic components.

In the world of PCB manufacturing, after-sales support plays a critical role in reducing repair costs and improving overall product longevity. Leveraging advanced technologies can lead to optimized repair processes that not only minimize downtime but also enhance customer satisfaction. A recent study highlighted that effective diagnostic tools can reduce PCB repair times by up to 30%, enabling companies to respond swiftly to malfunctions and thus prevent costly delays.

Moreover, the integration of AI-driven analytics into after-sales services offers significant potential. According to industry findings, organizations implementing predictive maintenance strategies have reported a 25% decrease in repair expenses. This technology analyzes real-time data from PCBs, guiding technicians on potential failures before they escalate into major issues. Such proactive measures not only save costs but also foster trust between manufacturers and consumers, as problems can be addressed more systematically and efficiently. By investing in these technological advancements, companies can not only streamline operations but also ensure sustainable growth in a competitive market.

Building strong relationships with customers is crucial for long-term success in PCB services. Engaging with customers and being responsive to their needs can lead to higher satisfaction rates and repeat business. To foster these relationships, companies should prioritize clear communication throughout the entire PCB design and manufacturing process. Regular updates and feedback sessions can help customers feel valued and informed, leading to enhanced loyalty and trust.

Tips for enhancing customer relationships include actively listening to customer concerns and suggestions, which can provide valuable insights into their needs. Offering personalized service and tailored solutions can also set a company apart in a competitive market. Additionally, following up after a sale demonstrates commitment to customer satisfaction and can uncover potential areas for improvement in the service delivery process.

Investing in customer education is another effective strategy. Providing resources such as tutorials, FAQs, and webinars not only empowers customers but also strengthens the relationship by positioning the company as an expert in the field. By cultivating these strong connections, PCB service providers can ensure continued success and reduce repair costs through proactive support and improved customer retention.