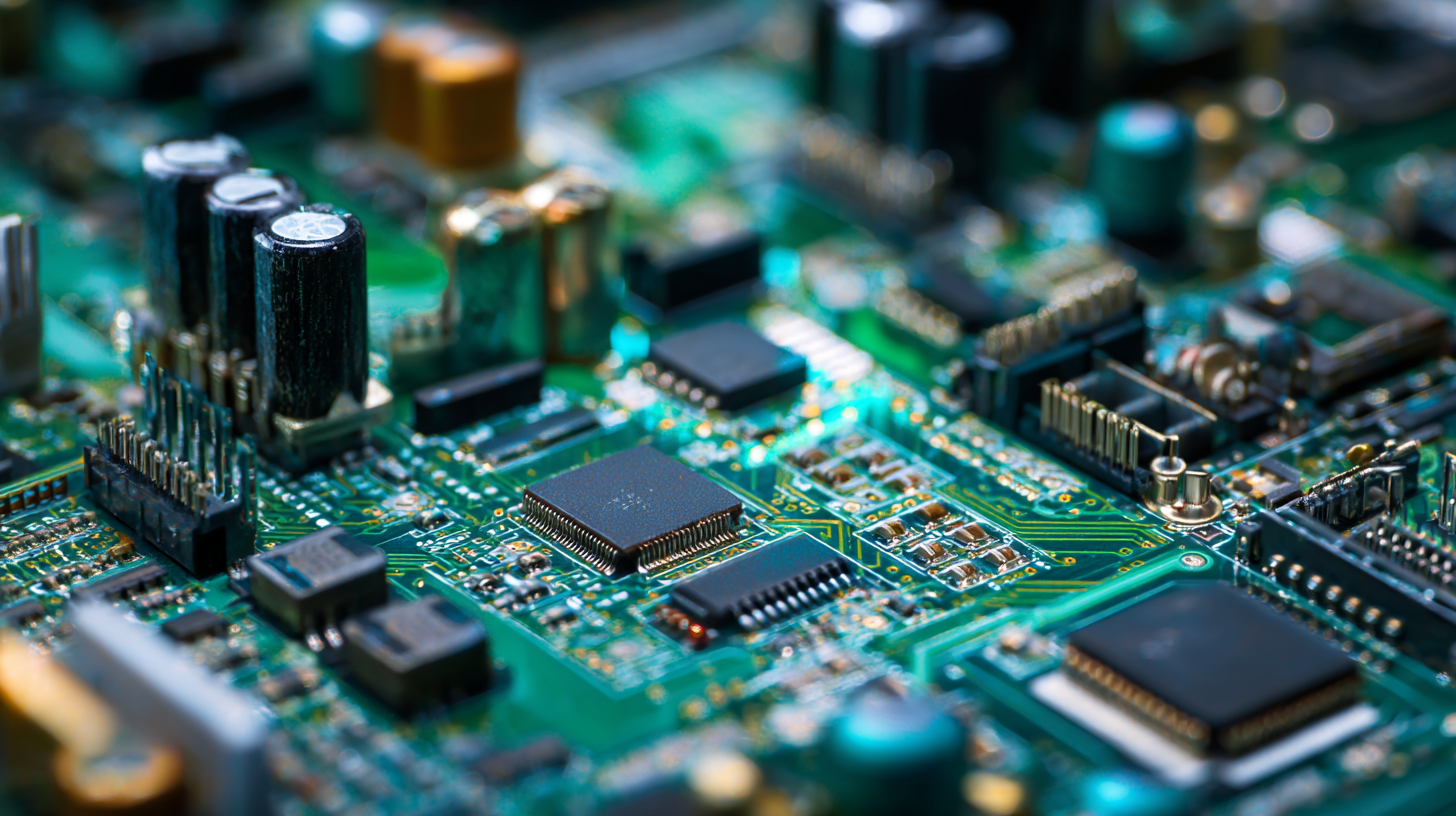

The evolution of technology has accentuated the significance of circuit board manufacturing, which serves as a backbone for numerous electronic devices we rely on daily. According to the global market report by Research and Markets, the circuit board manufacturing industry is projected to reach a valuation of over $85 billion by 2026, growing at a CAGR of approximately 3.9% from 2021. This growth is driven by increasing demands for electronic components across sectors such as automotive, consumer electronics, and telecommunications.

To stay competitive in this thriving market, mastering the fundamentals of circuit board manufacturing techniques is essential. This involves understanding the critical processes, materials, and innovations that contribute to high-quality and efficient production. As manufacturers face challenges such as component shortages and the push for sustainability, a solid grasp of these foundational skills will not only enhance production capabilities but also ensure adaptability to evolving industry standards and consumer expectations.

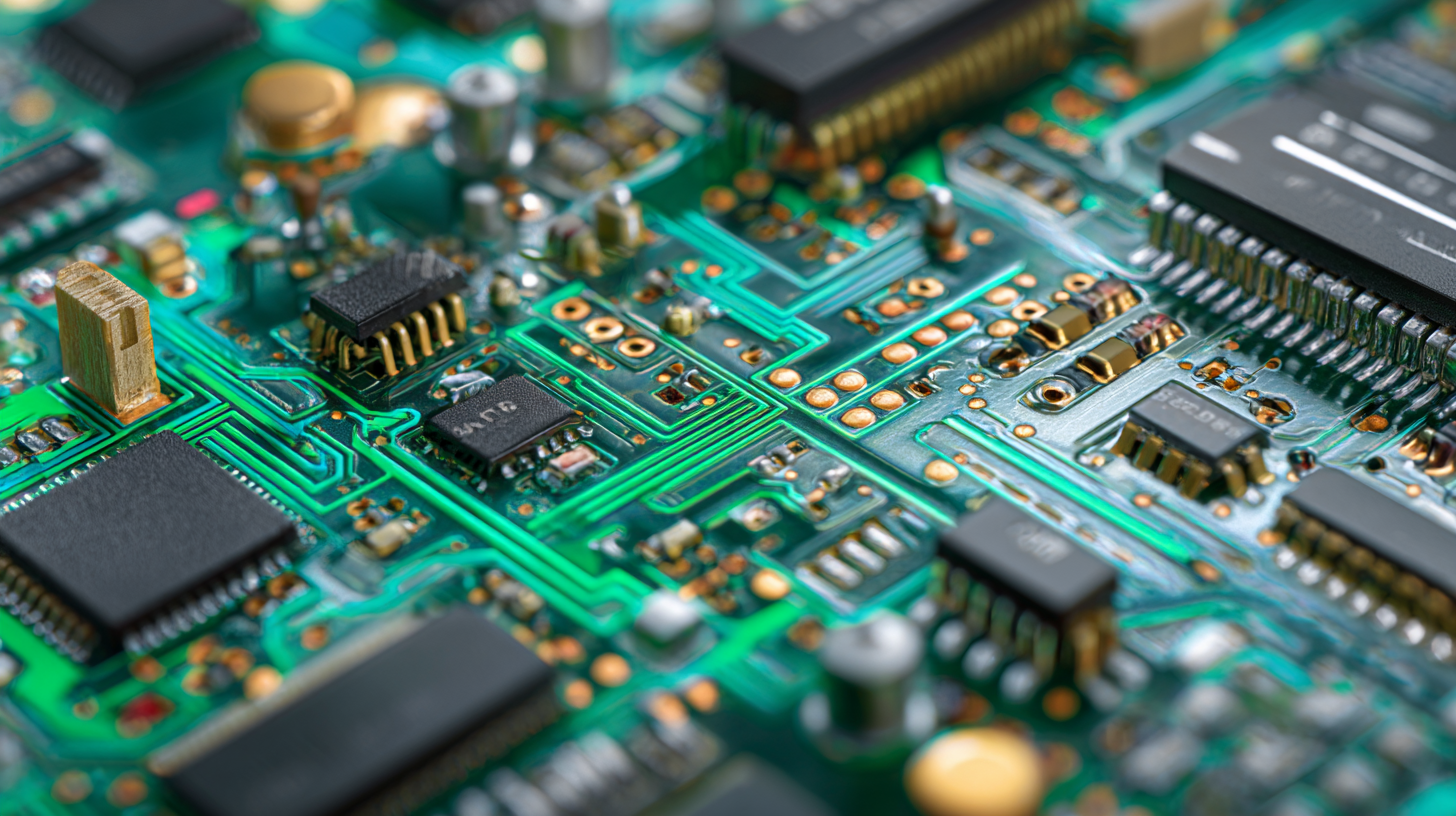

Understanding the basics of circuit board design and layout techniques is essential for anyone looking to excel in circuit board manufacturing. Effective design begins with grasping key concepts such as schematic design and component placement. A well-structured schematic provides a clear blueprint of the circuit, ensuring that all components are accurately represented. This foundation allows designers to visualize how each part interacts, which is crucial for troubleshooting and optimization during the manufacturing process.

Once the schematic is in place, the next crucial step is the layout of the circuit board itself. The layout involves deciding the physical placement of components on the board, routing connections between them efficiently while minimizing interference and signal loss. Designers need to consider factors like trace width, spacing, and overall board dimensions, as these can greatly impact the board's performance and manufacturability. By mastering these fundamental techniques, engineers can create reliable and efficient circuit boards that meet the demands of modern electronic applications.

The materials used in circuit board manufacturing play a crucial role in determining the performance, durability, and overall functionality of electronic devices. One of the most widely utilized materials is FR-4, a flame-retardant glass-reinforced epoxy laminate. This substrate is favored for its excellent electrical insulation properties and mechanical strength, making it ideal for a broad range of applications. Additionally, copper is the standard conductor for circuit traces due to its superior conductivity, affordability, and ease of etching.

Another key material is polyimide, known for its high-temperature resistance and flexibility. This makes polyimide suitable for flexible circuit boards, which are essential in compact electronic devices. Moreover, the choice of solder mask and surface finish also holds significant importance; the solder mask protects the copper traces from oxidation and enhances durability, while surface finishes like HASL (Hot Air Solder Leveling) prevent solder jump and improve solderability. Understanding these materials and their properties is essential for mastering circuit board manufacturing techniques, ensuring high-quality, reliable electronic products.

The field of PCB fabrication encompasses a variety of methods tailored to meet specific application requirements. Notably, techniques such as photolithography, etching, and plating are central to traditional PCB development, each offering distinct advantages. Photolithography allows for high precision in creating intricate designs, whereas etching efficiently removes unwanted material to define circuit pathways. Plating, especially in the context of multi-layer boards, enhances electrical connections and structural integrity.

Recent advancements in PCB manufacturing also reflect a shift towards innovative materials and technologies. For instance, the integration of superhydrophobic surfaces has shown potential in enhancing sensor applications, providing benefits like improved waterproofing and durability. Additionally, emerging methods in flexible electronics, such as the fabrication of lightweight composite structures, are paving the way for more versatile applications in wearable technology and smart devices. These developments, alongside traditional methods, highlight the evolving landscape of PCB fabrication, catering to the growing needs of modern electronic systems.

In the realm of circuit board production, quality control standards are paramount to ensure the reliability and performance of electronic devices. According to IPC-600, a widely recognized standard in the industry, nearly 90% of circuit boards fail to meet the minimum acceptability criteria due to issues such as insufficient solder or improper trace widths. This highlights the necessity for rigorous inspection processes throughout the manufacturing cycle.

Implementing automated optical inspection (AOI) systems has become critical, as recent studies indicate that companies adopting AOI experience a 20% reduction in defects, demonstrating the efficiency of technology in enhancing quality control.

Additionally, the integration of Six Sigma methodologies in circuit board manufacturing has shown to yield significant improvements in production processes. A report from the Electronics Industry Association noted that companies applying Six Sigma principles have reduced their production costs by up to 30% while simultaneously enhancing product quality. By focusing on defect reduction and process improvement, manufacturers can not only meet but exceed industry standards, ensuring their products are both reliable and competitive in a rapidly evolving market.

The commitment to stringent quality control not only safeguards a manufacturer's reputation but also fortifies customer trust in the end products.

The rise of automation in printed circuit board (PCB) manufacturing processes is reshaping the entire electronics landscape. As the PCB market is projected to grow significantly from 2025 to 2029, driven largely by smartphone adoption, manufacturers are increasingly leveraging advanced technologies. Automated optical inspection systems are becoming a cornerstone for ensuring quality control, with estimates suggesting a market growth to approximately USD 849.5 million by 2024. This represents a larger trend where automation not only enhances production efficiency but also addresses the complexity of modern manufacturing demands.

Furthermore, the shift towards Industry 4.0 emphasizes the necessity of integrating robotics and AI within manufacturing processes. As the automotive sector has demonstrated, with a significant portion of robotic installations, other industries are following suit. The push for automation within electronic manufacturing services highlights the urgency for manufacturers to adapt, streamlining operations and adopting AI agents to bolster productivity. As these technologies evolve, their role becomes critical in overcoming the challenges faced in the manufacturing arena, ultimately driving growth and innovation in PCB production techniques.

| Manufacturing Technique | Automation Level | Accuracy (%) | Production Speed (Units/Hour) | Cost Efficiency (%) |

|---|---|---|---|---|

| Manual PCB Assembly | Low | 85 | 20 | 70 |

| Wave Soldering | Medium | 90 | 30 | 75 |

| Pick and Place Automation | High | 95 | 100 | 85 |

| Surface Mount Technology (SMT) | High | 92 | 80 | 80 |

| Automated Optical Inspection (AOI) | High | 98 | 50 | 90 |