As the world progresses towards an ever-increasing reliance on technology, the demand for efficient and innovative processes in the manufacturing sector becomes paramount. In particular, the realm of PCB printing is undergoing a significant transformation, driven by emerging technologies and trends that not only enhance production capabilities but also influence global procurement strategies. This blog will explore the current innovations in PCB printing, including advancements in materials, automation, and sustainable practices, and how these developments are reshaping the landscape of supply chain management. As we delve into the future of PCB printing, we will highlight the implications for industry stakeholders and the strategic shifts they must navigate to remain competitive in a rapidly evolving market.

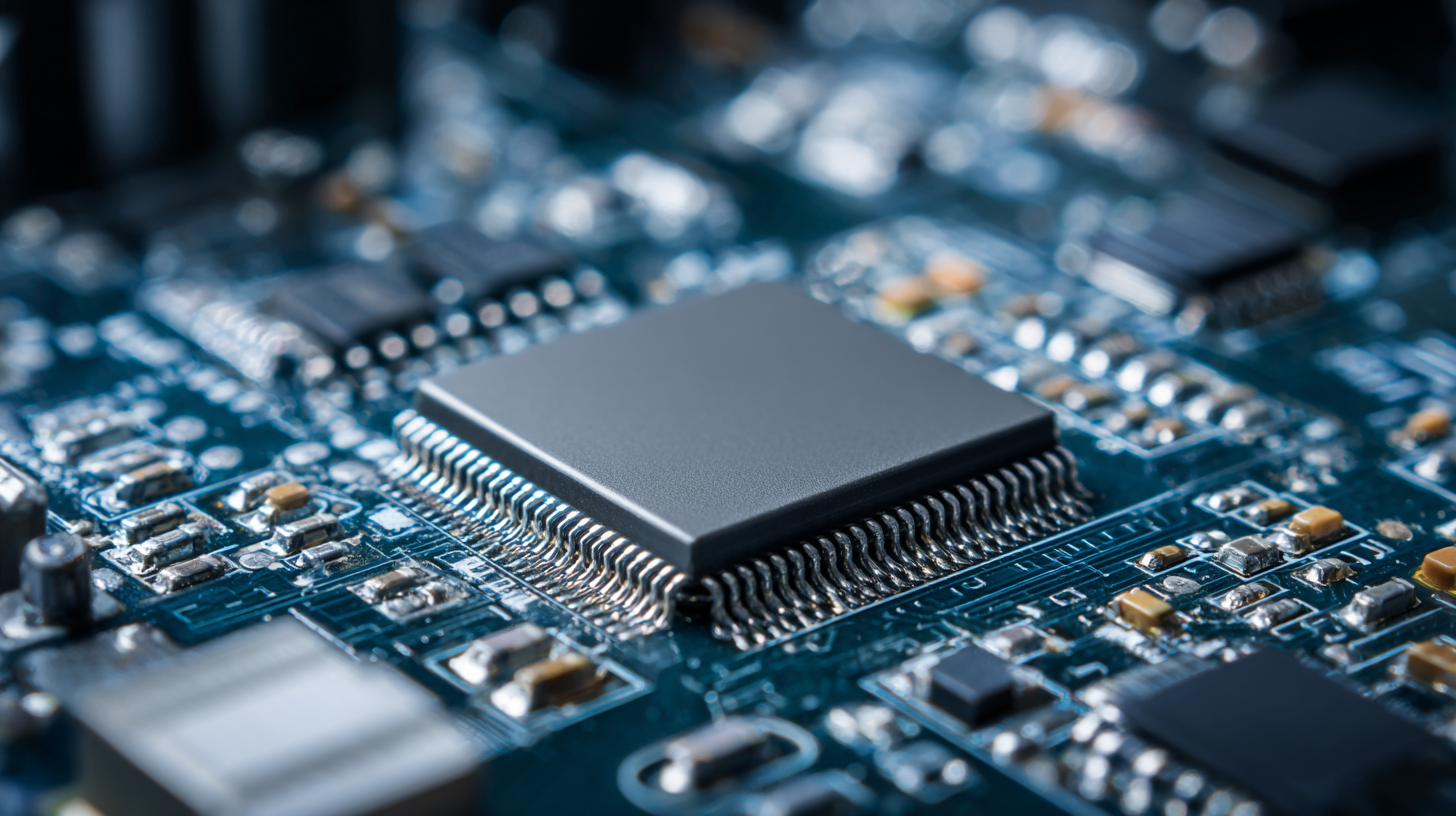

The landscape of PCB printing is undergoing a remarkable transformation, fueled by emerging technologies that are redefining the processes involved in manufacturing printed circuit boards. Advanced materials such as conductive inks and nanomaterials are making it possible to create lighter, more efficient circuits that can be printed with unprecedented precision. These innovations not only enhance the performance of PCBs but also contribute to the reduction of waste during production, aligning with the growing demand for sustainable manufacturing practices.

Moreover, automation and smart manufacturing technologies are streamlining the PCB printing process. With the integration of AI and machine learning, manufacturers can optimize production schedules and improve quality control, ensuring that each board meets rigorous standards. This level of efficiency not only reduces costs but also accelerates the time-to-market for new products, enabling companies to respond swiftly to changing consumer demands. As these technologies continue to evolve, they are set to revolutionize global procurement trends, allowing businesses to adopt more agile and cost-effective solutions for their PCB needs.

| Innovation | Description | Impact on Procurement | Adoption Rate (%) |

|---|---|---|---|

| 3D Printing | Allows for rapid prototyping and manufacturing of PCBs with complex geometries. | Reduces lead times and enables customization. | 35 |

| Flexible PCBs | Enables the design of lightweight and compact devices by using bendable materials. | Enhances design flexibility and reduces weight. | 25 |

| AI in PCB Design | Utilizes AI algorithms to optimize PCB layouts and enhance performance. | Improves efficiency and minimizes errors during design. | 40 |

| Material Advancements | Involves using advanced materials for better conductivity and durability. | Enhances performance and longevity of PCBs. | 30 |

| IoT Integration | Incorporates IoT technology for smarter tracking and monitoring of PCB supply chains. | Improves transparency and efficiency in procurement processes. | 20 |

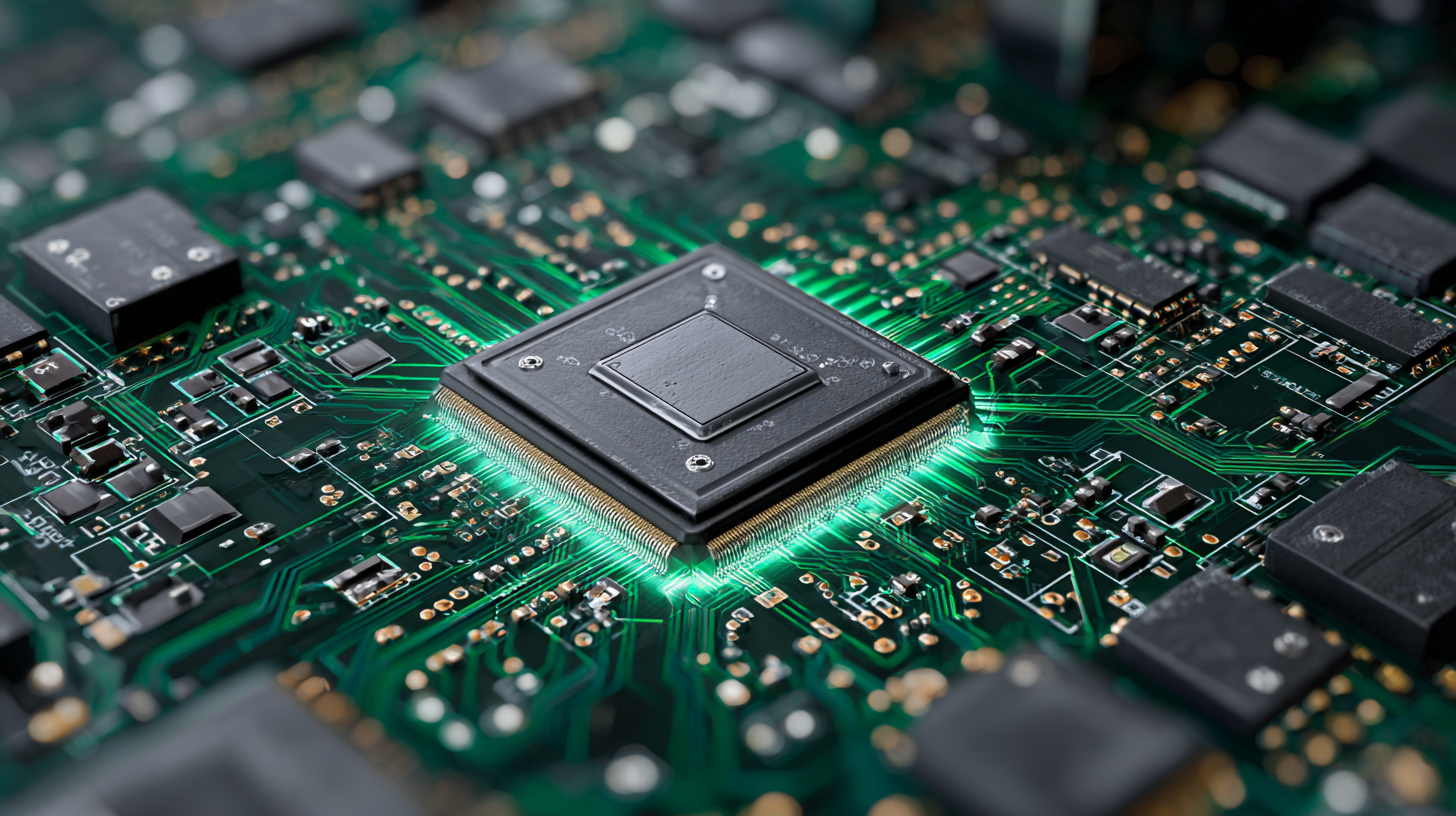

As the landscape of printed circuit board (PCB) production evolves, sustainability has emerged as a paramount concern. The increasing awareness of environmental impact is driving manufacturers to adopt eco-friendly innovations. From utilizing biodegradable materials to implementing energy-efficient production processes, these advancements not only reduce waste and carbon footprints but also align with the growing demand for sustainable electronics. This shift is transforming PCB procurement practices globally, pushing suppliers to prioritize sustainability in their offerings.

Additionally, several companies are exploring the use of recycled materials in their PCB production. By repurposing electronic waste, manufacturers can significantly mitigate the depletion of natural resources and minimize landfill contributions. Furthermore, the integration of green technologies, such as water-based soldering processes and advanced waste management systems, streamlines operations while promoting a cleaner production environment. These innovations not only enhance the eco-friendliness of PCB manufacturing but also appeal to environmentally conscious consumers and businesses, driving a new trend in global procurement strategies.

This chart illustrates the percentage of PCB manufacturers focusing on sustainability innovations and eco-friendly practices in their production processes over the past five years. The data highlights a growing trend towards environmentally responsible PCB production methods.

As we delve into the future of PCB (Printed Circuit Board) printing, the integration of AI and automation is revolutionizing design and manufacturing processes. Advances in technology are addressing the increasing complexity of electronic product designs, allowing engineers to meet the demands of the modern market more effectively. Recent industry events have highlighted collaborative efforts between organizations to explore AI's potential in enhancing PCB design methodologies, ensuring products are not only efficient but also capable of functioning in multifaceted environments.

AI-driven tools are streamlining the design phase by offering intelligent recommendations, automating repetitive tasks, and simulating multiple physical factors. This innovation enables designers to visualize and optimize PCB layouts with unprecedented speed and accuracy. As a result, automation plays a critical role in reducing production time while mitigating human error, ultimately leading to increased reliability in manufactured products. The focus on combining AI with automation not only supports the technical requirements of advanced electronic systems but also aligns with global procurement trends aimed at sustainability and cost-effectiveness.

As the global supply chain landscape evolves, procurement strategies are adapting in response to shifts in market dynamics and technological advancements. According to a recent study by Gartner, 79% of supply chain leaders anticipate significant adjustments in their strategies to accommodate new technologies and evolving consumer demands. This transformation is particularly evident in the printed circuit board (PCB) sector, where innovations such as additive manufacturing and smart automation are redefining production processes.

Moreover, the COVID-19 pandemic has accelerated the need for resilience in supply chains, prompting companies to rethink their procurement approaches. A report by McKinsey highlights that 93% of executives believe that the pandemic's impact necessitates the adoption of digital tools for greater flexibility and responsiveness. Emphasizing collaboration and transparency in procurement practices will be crucial for businesses aiming to thrive in an increasingly interconnected market.

As organizations prioritize sustainable sourcing and enhanced supplier relationships, the future of PCB printing is set not only to enhance production efficiency but also to foster a more adaptive procurement environment.

The global market for printed circuit boards (PCBs) is witnessing significant transformations, driven by evolving consumer demands and technological advancements. By 2025, the automotive PCB market is projected to grow from a valuation of $9.15 billion in 2023 to approximately $15.1 billion, reflecting a robust compound annual growth rate (CAGR) of 5.9%. This growth highlights the increasing integration of electronic components in vehicles, a trend that is surging due to the rise of electric and autonomous vehicles.

Additionally, the heavy copper PCB market is expected to thrive, with projections indicating considerable growth across various types—ranging from finished copper of 2 ounces to as high as 5 ounces. This market's expansion is predominantly driven by applications in sectors such as consumer electronics, telecommunications, and healthcare, capitalizing on their enhanced thermal and electrical performance characteristics. Reports suggest that by 2033, the heavy copper PCB market will continue to adapt, catering to the diversified needs of an increasingly digital world as demand for high-performance electronic devices escalates.