Flexible PCBs (Printed Circuit Boards) have emerged as a revolutionary solution in the realm of electronics, allowing for greater versatility and innovation in design and function. Unlike traditional rigid PCBs, flexible PCBs can be bent, coiled, and folded, accommodating a wide range of applications across various industries. This adaptability enables engineers and designers to create lighter, more compact devices without compromising on performance. The ability to fit into tighter spaces while maintaining electrical connectivity has made flexible PCBs particularly appealing for modern consumer electronics, medical devices, and automotive applications.

Moreover, flexible PCBs boast several advantages, such as reduced weight and size, improved thermal conductivity, and enhanced reliability. These benefits play a pivotal role in allowing manufacturers to meet the growing demand for high-density interconnection technology, all while ensuring longevity and durability. As we explore the intricacies of flexible PCBs, we will delve into their unique attributes, diverse applications, and the significant impact they have on driving innovation in the electronics industry today. Understanding these elements is essential for anyone looking to stay at the forefront of technology and design in an ever-evolving market.

Flexible printed circuits, or flexible PCBs, are a type of electronic circuit board that can bend, twist, and fold without damaging the components printed on them. Unlike traditional rigid circuit boards, flexible PCBs are made from materials that allow them to conform to various shapes and sizes, making them ideal for applications where space is limited or complex geometries are required. Their construction typically involves layers of conductive traces and insulating materials, which contribute to their lightweight and compact nature.

The unique characteristics of flexible PCBs enable them to be used in a wide range of applications. These include consumer electronics, medical devices, automotive systems, and aerospace technologies, where versatility and reliability are crucial. Their flexibility can simplify the design of electronic devices, providing more room for components while also reducing the weight of the assembly. Furthermore, flexible PCBs can enhance the performance of electronic systems by minimizing the effects of stress and strain that might occur in more rigid materials, thus improving the overall longevity and functionality of the devices in which they are employed.

Flexible printed circuit boards (FPCBs) are notable for their unique characteristics that set them apart from traditional rigid PCBs. One of the most distinctive features of flexible PCBs is their ability to bend and twist without compromising electrical performance. This flexibility allows for innovative designs in a variety of applications, enabling devices to be more compact and lightweight. The materials used in flexible PCBs, such as polyimide or polyester, provide not only durability but also the capacity to withstand high temperatures and various environmental conditions.

Another key characteristic of flexible PCBs is their high density and integration capability. They can accommodate more complex circuit designs and densely packed components, which is essential for modern technology trends that demand miniaturization. Additionally, FPCBs exhibit excellent electrical performance, with lower impedance and reduced signal loss compared to traditional boards. Their lightweight nature and compatibility with surface mount technologies also enhance efficiency in manufacturing and assembly processes. Such attributes make flexible PCBs particularly suited for applications ranging from consumer electronics to aerospace, automotive, and medical devices, where space and reliability are critical.

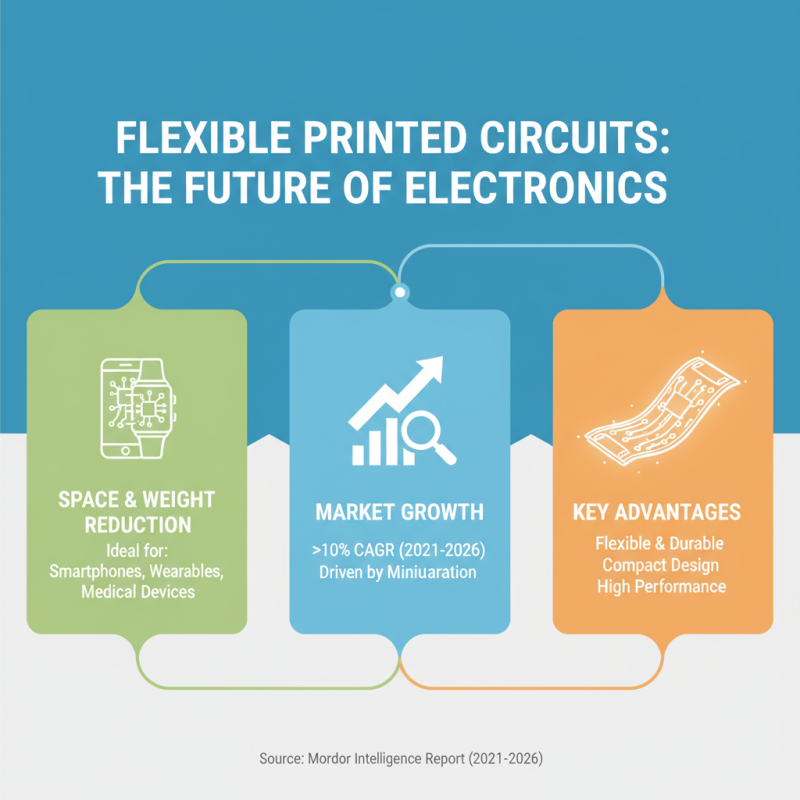

Flexible printed circuits (FPCs) have gained significant traction in the electronics industry due to their unique properties and advantages over traditional rigid circuit boards. One of the primary benefits of using flexible PCBs is their ability to significantly reduce space and weight in electronic devices. A report by the global market research firm, Mordor Intelligence, indicates that the flexible PCB market is expected to grow at a CAGR of over 10% from 2021 to 2026, largely driven by the increasing demand for miniaturized electronic components. This trend highlights the importance of FPCs in applications where space constraints are critical, such as in smartphones, wearable devices, and medical equipment.

In addition to space efficiency, flexible PCBs offer enhanced durability and reliability. They are designed to withstand bending and flexing without compromising their functionality, making them ideal for portable electronics that require movement. According to a study published in the Journal of Electronics Manufacturing, flexible PCBs can endure over 10,000 flex cycles compared to rigid boards, which experience failure after a much lower number of cycles. This flexibility not only improves the lifespan of electronic products but also opens up new possibilities for design innovation in various applications, from aerospace to automotive. As industries continue to embrace these advantages, the adoption of flexible PCBs is poised to accelerate significantly.

Flexible PCBs, or printed circuit boards, have gained prominence across various industries due to their ability to bend and conform to compact spaces. One of the primary applications of flexible PCBs is within consumer electronics, where they enable the design of slimmer, lighter devices without sacrificing performance. These flexible circuits are commonly found in smartphones, tablets, and wearables, allowing for intricate layouts that optimize space and weight.

Another significant application is in the automotive industry, particularly in advanced driver-assistance systems (ADAS). Flexible PCBs are ideal for connecting various sensors and control units, providing reliable performance even under the harsh conditions of automotive environments. Additionally, they play a crucial role in medical devices, where compact designs and biocompatibility are essential for patient safety and equipment efficiency.

Tip: When considering the use of flexible PCBs, it’s important to evaluate the specific requirements of your project, including environmental conditions and design complexity. This will help ensure that you choose the most suitable materials and manufacturing processes.

Moreover, the aerospace sector has also embraced flexible PCBs. Their lightweight nature, coupled with high reliability, makes them perfect for applications in aircraft instrumentation and satellite technology, where space and weight savings are critical. As technology continues to evolve, the applications of flexible PCBs are set to expand even further, enabling innovative designs that meet the demands of modern electronics.

When comparing flexible PCBs to traditional rigid PCBs, several key differences emerge, shaping their application suitability in various industries. Flexible PCBs are made from bendable materials that allow them to be easily manipulated to fit into compact spaces and around corners, making them ideal for devices with limited space or dynamic movement, such as wearables and medical devices. In contrast, rigid PCBs are constructed from a solid base material, offering stability and durability but lacking flexibility. This makes them suitable for applications where the circuit board must remain fixed, such as in desktop computers and stationary electronics.

One of the primary advantages of flexible PCBs is their lightweight nature, leading to reduced overall product weight and enhancing portability. Additionally, the ability to design multi-layer configurations helps in saving space, allowing for more compact device designs. However, rigid PCBs excel in high-power applications where stability and heat dissipation are crucial, making them the preferred choice for high-performance computing devices.

Tips: When choosing between flexible and rigid PCBs, consider the specific requirements of your device's design and application environment. Evaluate factors like size constraints, weight considerations, and the potential for movement to determine which type is best suited. Always consult with a PCB design expert to ensure you maximize the benefits of whichever technology you choose.