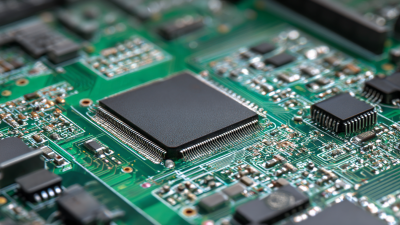

In the ever-evolving landscape of electronics, the demand for multi circuit boards has surged, necessitating innovative design and manufacturing techniques. These intricate boards, which host multiple circuits on a single substrate, play a crucial role in optimizing space, enhancing functionality, and reducing production costs. As the complexity of electronic devices increases, so does the need for efficient methods of creating multi circuit boards that can meet the rigorous demands of modern applications.

Effective design and manufacturing processes are essential for ensuring the reliability and performance of multi circuit boards. Engineers and manufacturers must navigate various challenges, including thermal management, signal integrity, and component density. This article aims to explore best practices and cutting-edge methodologies that can streamline the production of multi circuit boards, ensuring that they meet the technical and commercial requirements of today’s fast-paced market. By focusing on the interplay between design innovation and manufacturing excellence, we can pave the way for the next generation of electronic devices that utilize multi circuit boards to their full potential.

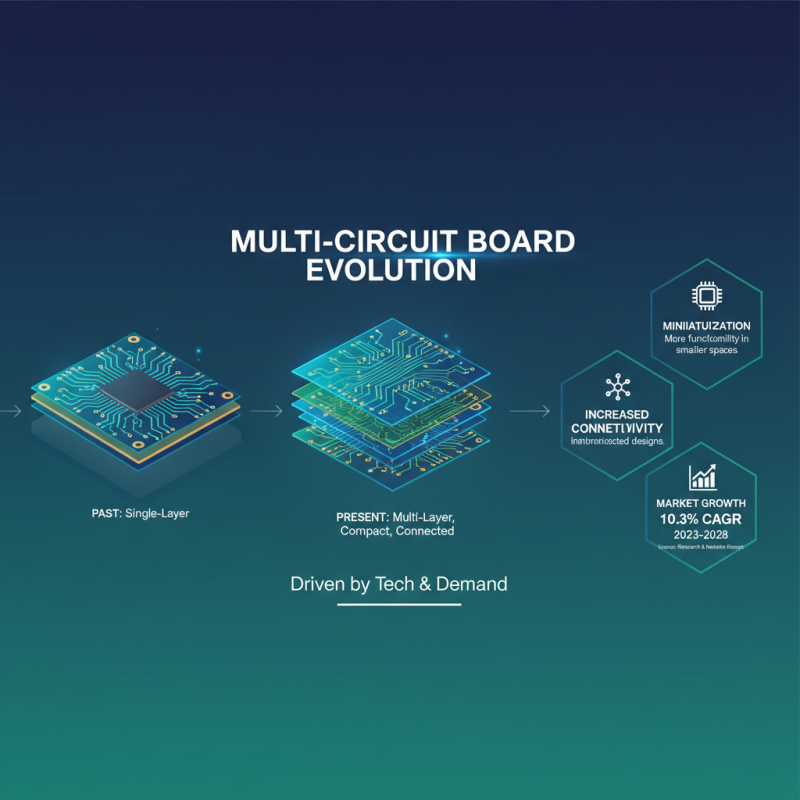

Multi Circuit Board (MCB) technology has emerged as a critical innovation in the electronics manufacturing sector, with diverse applications across various industries. According to a market research report by Allied Market Research, the global printed circuit board market is projected to reach $98 billion by 2025, driven largely by the increasing demand for miniaturized electronics and enhanced functionality in devices. MCBs facilitate this advancement by allowing multiple electronic circuits to be integrated into a single board, thereby optimizing space and boosting performance efficiency.

The applications of MCB technology are extensive, ranging from consumer electronics to aerospace and automotive sectors. In the automotive industry, for instance, the shift toward electric vehicles (EVs) is accelerating the demand for sophisticated circuit designs that can manage complex systems like power distribution and battery management efficiently. A report from Research and Markets estimates that the automotive printed circuit board market will grow significantly, reaching approximately $30 billion by 2025. This growth underscores the necessity for manufacturers to adopt effective design practices that leverage MCB technology to meet the evolving industry standards while ensuring reliability and scalability in their products.

When designing multi circuit boards (MCBs), optimizing the layout is crucial for achieving high performance and reliability. One key principle is to minimize the length of signal traces. Shorter traces not only reduce the potential for electromagnetic interference but also improve signal integrity. This involves strategically placing components in a manner that shortens the pathways for critical signals, thus ensuring faster data transmission and lower latency. Additionally, designers should consider the use of ground planes to provide a solid return path for signals, which can further enhance performance.

Another important aspect is thermal management. MCBs often generate heat during operation, which can affect performance and reliability. Effective layout design should include thermal vias and strategically placed heat sinks to dissipate heat away from sensitive components. It is also vital to consider the spacing between components to facilitate airflow and allow for adequate cooling. Implementing these design principles not only contributes to the longevity of the circuit board but also supports the overall efficiency of the electronic system.

| Principle | Description | Impact on Performance | Implementation Difficulty |

|---|---|---|---|

| Signal Integrity | Ensuring minimal interference and crosstalk between circuits | High | Medium |

| Thermal Management | Designing for heat dissipation to avoid damage | High | High |

| Layer Stack-Up | Choosing the right number of layers and their arrangement | Medium | Medium |

| Grounding Techniques | Implementing effective grounding to reduce noise | High | Low |

| Component Placement | Strategically placing components for functionality and ease of access | Medium | Medium |

When designing and manufacturing multi circuit boards, understanding essential manufacturing processes is crucial for achieving efficiency and reliability. The first step in this journey involves precise PCB layout and design. Utilizing advanced software tools enables designers to create intricate layouts that optimize space and enhance performance. It's important to consider factors such as signal integrity and thermal management at this stage to prevent issues that may arise later in the manufacturing process. Effective collaboration between design engineers and manufacturers ensures that the design can be translated into a functional product without compromising quality.

Once the design is finalized, the next key manufacturing process is material selection. Choosing the right substrate material, such as FR-4 or polyimide, can significantly impact the board’s performance and durability. Additionally, processes like etching, layering, and soldering must be executed with precision to ensure the boards meet the required specifications. Employing automated assembly techniques not only speeds up production but also minimizes the risk of human error. Implementing rigorous quality control measures throughout the process guarantees that each multi circuit board is built to the highest standards, ready to meet the demands of modern electronics.

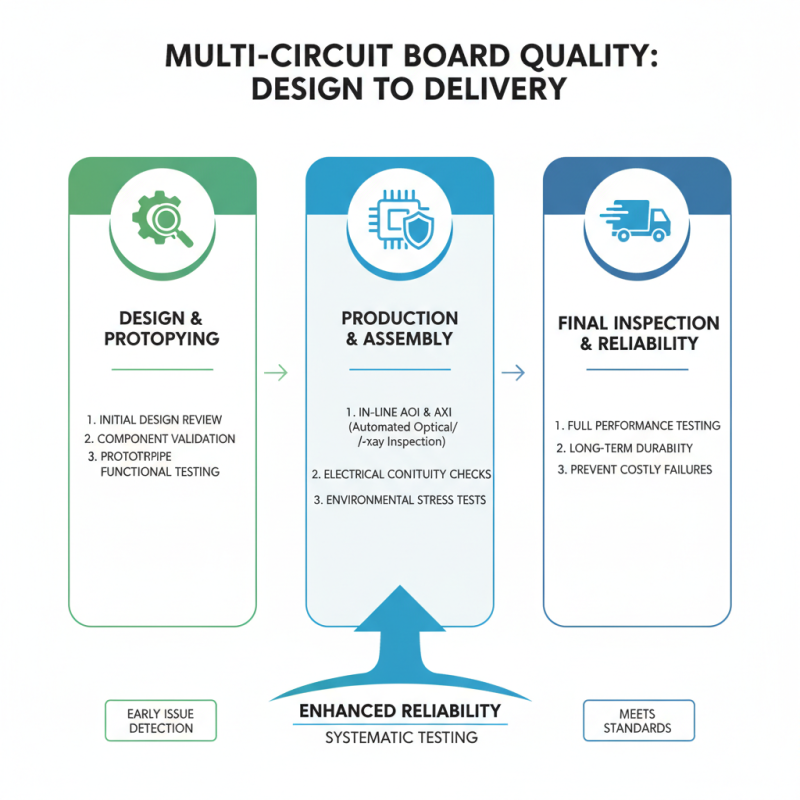

Quality control and testing methods are crucial in the design and manufacture of multi circuit boards. Ensuring that each circuit board meets stringent performance standards not only enhances reliability but also prevents costly failures down the line. Implementing systematic testing at various stages of production, from initial prototype testing to final inspections, allows manufacturers to identify and address potential issues early in the process.

One effective approach is to incorporate automated optical inspection (AOI) during the manufacturing phase. This method quickly detects surface defects such as misalignments or soldering issues that might elude human eyes. Regularly scheduled performance validation tests, such as functional and stress tests, can further guarantee that the circuit boards function correctly under operational conditions.

Tips: To maintain high quality standards, establish a checklist covering all essential tests before moving to the next production stage. Additionally, training your team on the latest testing technologies and methods can lead to significant improvements in both efficiency and accuracy. Engaging in peer reviews of test results can also foster collaboration and knowledge sharing, ensuring that your quality control processes remain robust and reliable.

The landscape of multi circuit board design and manufacturing is rapidly evolving, driven by advancements in technology and changing market demands. With the increase in miniaturization and connectivity, the industry is seeing a shift towards more complex designs that allow for multiple circuits to coexist within a single board. According to a recent market analysis report by Research and Markets, the multi-layer PCB market is projected to grow by 10.3% from 2023 to 2028, reflecting the trend towards increased functionality in compact formats.

As manufacturers embrace innovative design techniques such as computer-aided design (CAD) and automated assembly processes, the challenge remains to maintain quality while enhancing production efficiency. Emerging techniques such as additive manufacturing and advanced materials are set to redefine traditional approaches, allowing for faster prototyping and a substantial reduction in material waste. For instance, the adoption of high-frequency laminates is becoming more common, facilitating the production of boards that can support high-speed data transmission and sophisticated electronic applications.

**Tips**: To optimize your PCB design, prioritize the layout of conductive pathways to reduce signal interference and ensure efficient heat dissipation. Additionally, consider implementing Design for Manufacturability (DFM) principles early in the design phase to streamline production and minimize potential errors. Keeping abreast of the latest industry standards and compliance regulations will also enhance your product's reliability in the market.