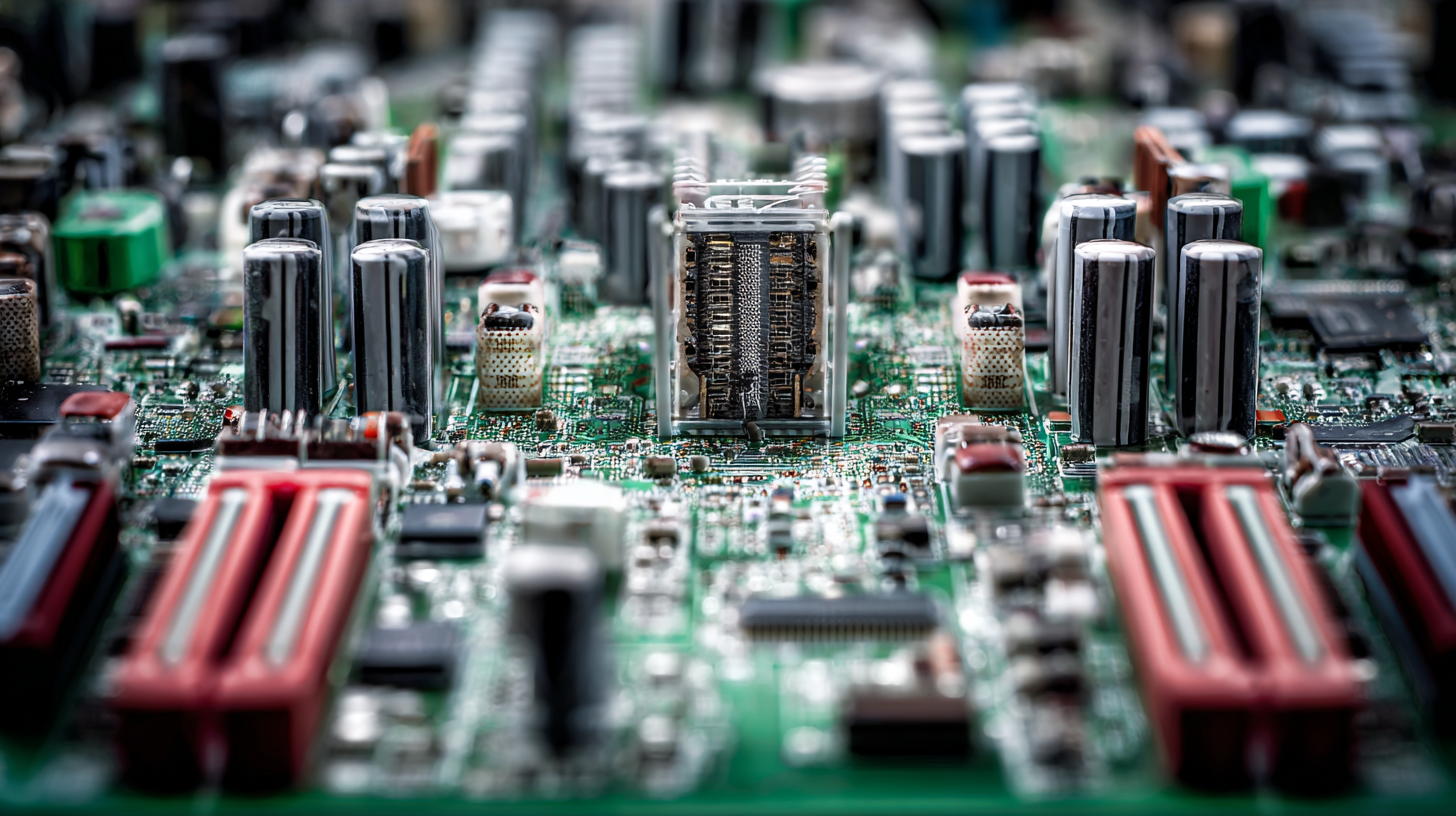

In the rapidly evolving electronics industry, selecting the right PCB assembly partner can significantly impact product quality, performance, and overall success. According to a report by IPC, the global market for PCB assembly services is projected to reach $70 billion by 2025, underscoring the critical role that assembly partners play in a company's supply chain. A high-quality PCB assembly not only ensures the reliability of electronic products but also enhances manufacturing efficiency and reduces time-to-market. With the increasing complexity of designs and the demand for miniaturization, choosing the best PCB assembly partner becomes paramount for companies aiming to maintain a competitive edge. This comprehensive understanding of the benefits associated with quality PCB assembly partnerships will guide businesses in making informed decisions that align with their strategic goals.

When it comes to PCB assembly, selecting the right partner is crucial for the success of your projects. Key factors to consider include the partner's experience in the industry, the quality of their manufacturing processes, and their capability to provide ongoing support and communication. A partner with a proven track record in PCB assembly ensures that you receive high-quality products that meet your specific requirements and standards.

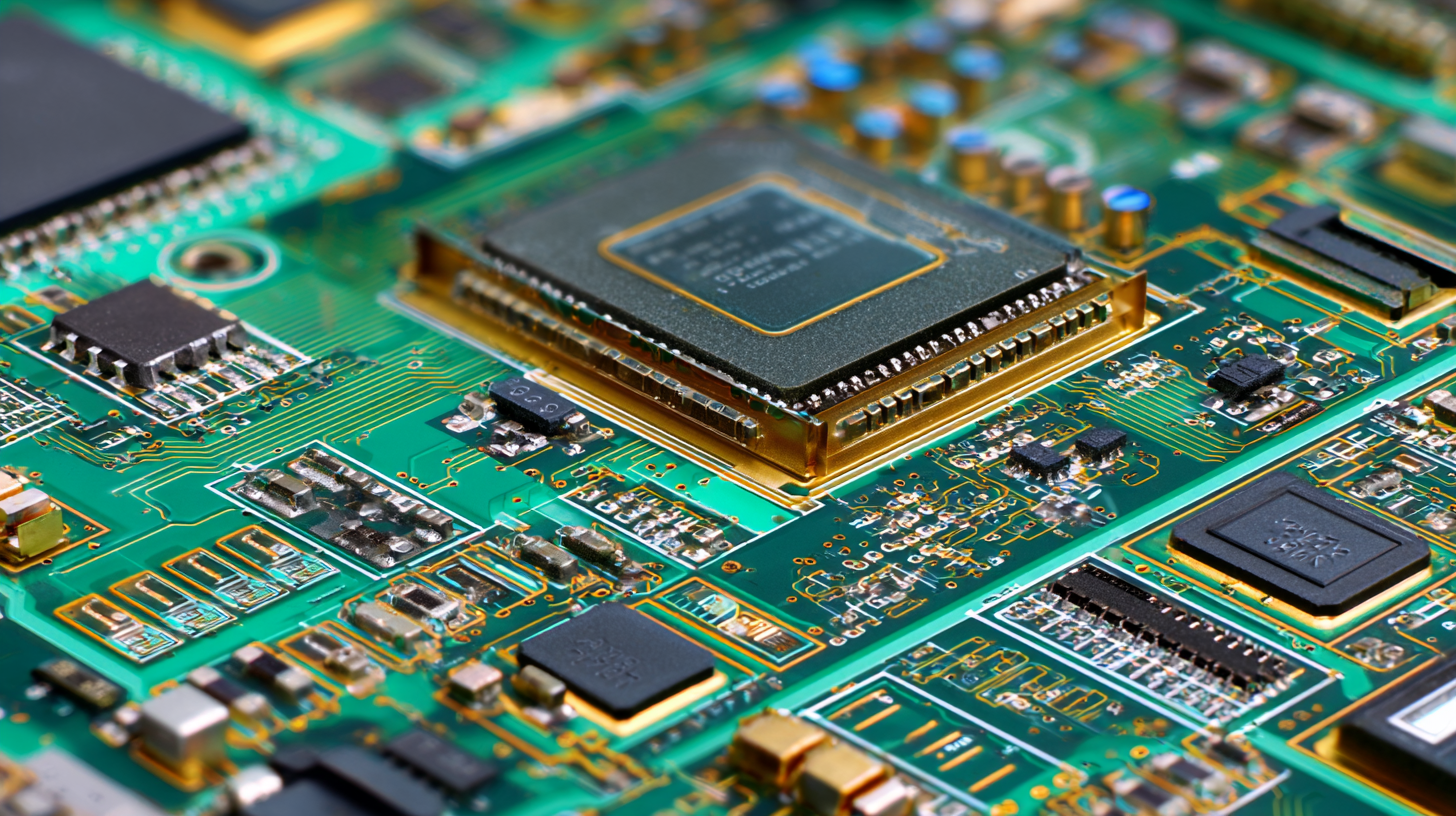

Tips for selecting the best PCB assembly partner include evaluating their certifications and compliance with industry standards, such as ISO 9001. This not only reflects their commitment to quality but also ensures that they employ best practices in their manufacturing processes. Another important factor is their flexibility in addressing project-specific needs; a good partner should be able to adapt their services based on your unique requirements.

Finally, consider the partner's communication and customer service capabilities. An effective PCB assembly partner should establish clear communication channels and be responsive to your inquiries. Regular updates and feedback loops can significantly enhance project collaboration, ensuring that potential issues are addressed proactively and that your project stays on track.

In today's fast-paced technological landscape, the significance of high-quality PCB assembly cannot be overstated. Industries ranging from automotive to medical devices rely on precision-engineered printed circuit boards (PCBs) for their electronic systems. For example, in the automotive sector, manufacturers are increasingly integrating advanced driver-assistance systems (ADAS) that require reliable and efficient PCB assemblies. A faulty PCB could compromise vehicle safety features, demonstrating how quality directly influences performance and customer trust.

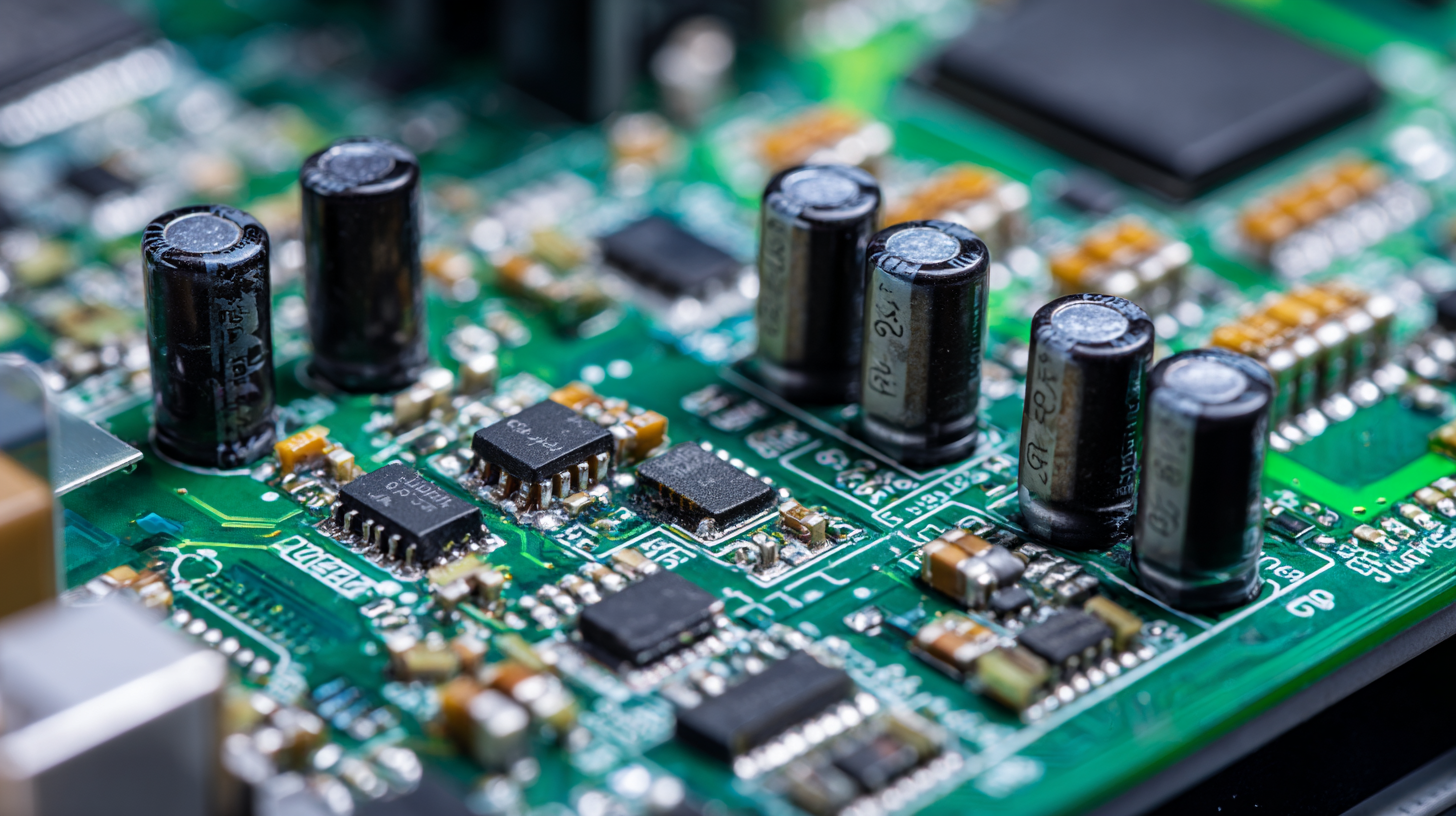

Similarly, in the medical field, the demand for accurate and dependable PCB assembly is paramount. Devices such as pacemakers and diagnostic equipment must operate flawlessly to ensure patient safety and effective healthcare delivery. Choosing a reputable PCB assembly partner enables manufacturers to not only meet regulatory standards but also to enhance the overall reliability of their products.

This choice proves crucial as firms strive for innovation while maintaining quality assurance, ultimately driving their industry success in a competitive market.

When selecting the best PCB assembly partner, it’s crucial to evaluate their capabilities thoroughly. Key considerations include their production capacity, technology expertise, and quality assurance processes. According to the IPC’s 2022 report on PCB manufacturing trends, companies that invest in advanced automation and robotics see productivity increases of 20-30%. This is essential for meeting the growing demand for shorter lead times and higher component densities in modern electronics.

Furthermore, assessing a partner’s certifications can provide insights into their commitment to quality. Many leading PCB assembly firms maintain certifications such as ISO 9001 and IPC-A-610, which signify adherence to international quality standards. In a survey conducted by PCB Research Institute, 85% of manufacturers reported that working with certified partners improved their product reliability and reduced the rate of defects. By prioritizing these factors, companies can ensure that their PCB projects are in capable hands, ultimately leading to better performance and customer satisfaction.

When selecting a PCB assembly partner, the balance between cost and quality is crucial for long-term success. Cost considerations are often the first factor that comes to mind; however, opting for the lowest price can lead to compromises in quality that detrimentally affect product performance and reliability. The past decade has shown that investing in high-quality PCB assembly not only enhances product lifespan but also reduces costs associated with defects, recalls, and customer dissatisfaction. As industries evolve, especially in the face of disruptive manufacturing changes and supply chain challenges, the importance of solid partnerships with reputable assembly providers cannot be overstated.

Understanding the nuanced dynamics of supply chain management is essential in making informed decisions regarding PCB assembly. As modern manufacturing increasingly leverages advanced technologies like AI and machine learning, it becomes imperative to collaborate with partners who prioritize quality alongside cost efficiency. The evolving landscape demands a strategy that embraces resilience without sacrificing performance. By aligning with partners that value quality, businesses can ensure they remain competitive while fostering innovation and sustainability within their production processes, ultimately leading to greater business success in an ever-changing global market.

Choosing the right PCB assembly partner can significantly streamline your production process, allowing for efficient resource management and improved product quality. A dependable partner not only brings expertise but also enhances communication throughout the production cycle. This ensures that design changes or production challenges are addressed in real-time, minimizing delays and reducing operational costs.

**Tip 1:** When selecting a PCB assembly partner, assess their capabilities and experience in your specific industry. Look for a company that has a proven track record of handling similar projects, as this can help ensure they understand the unique requirements and regulatory standards that apply to your product.

**Tip 2:** Prioritize partners that offer comprehensive services, from prototyping to full-scale production. This allows for seamless transitions between different stages of development and helps maintain consistency in quality and performance. A single partner managing the entire assembly process can create efficiencies that ultimately enhance your overall production timeline.

**Tip 3:** Don’t overlook the importance of communication. Establish clear lines of communication and regular updates with your PCB assembly partner. This proactivity can help identify potential issues early and fosters a collaborative environment that can lead to innovative solutions and faster turnaround times.