In recent years, the landscape of PCB fabrication and assembly has undergone significant transformations driven by technological advancements and market demands. With the global market value of PCB fabrication and assembly projected to reach over $80 billion by 2025, it is crucial for industry players to stay ahead of emerging trends. According to a report by Allied Market Research, the increasing demand for consumer electronics and the rise of electric vehicles are key factors fueling this growth, leading to innovative practices in manufacturing.

John Smith, an esteemed expert in PCB technology and a consultant for leading electronic firms, emphasizes the importance of adapting to these changes, stating, “The future of PCB fabrication and assembly is not just about cost reduction, but also about the ability to innovate and integrate advanced technologies to meet diverse customer needs.” As we look towards 2025, it is essential to explore the top trends shaping this sector, ranging from the adoption of AI and automation to sustainable manufacturing practices. Understanding these trends will help companies optimize their operations, enhance product quality, and maintain competitive advantages in an increasingly complex market.

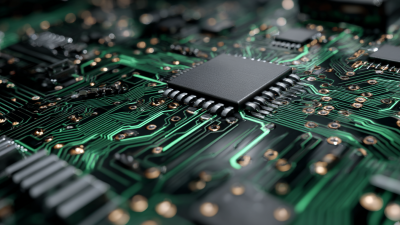

The advancements in PCB fabrication technology in 2025 promise to revolutionize the electronics industry by enhancing efficiency and precision.

One significant trend is the adoption of more sophisticated materials, such as flexible and high-frequency laminates, which cater to the needs of next-generation applications like 5G and IoT devices. These materials not only improve performance but also allow for innovative designs that can accommodate tighter spaces and complex circuit layouts.

Moreover, automation and artificial intelligence are set to play a pivotal role in PCB assembly processes. With the integration of machine learning algorithms, manufacturers can expect more refined quality control measures and faster production cycles. Automated inspection systems, powered by AI, enable real-time detection of defects, thereby minimizing waste and reducing manufacturing costs.

As a result, companies will be better positioned to meet the growing demand for high-quality PCBs in various sectors, including automotive, telecommunications, and consumer electronics.

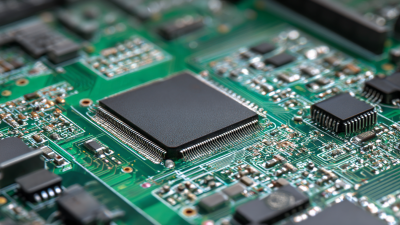

In 2025, the landscape of PCB fabrication and assembly is set to transform significantly, driven by emerging materials that enhance performance and efficiency. One of the most promising materials making waves in the industry is high-frequency laminate, which is ideal for RF and microwave applications. These laminates enable PCBs to operate at higher frequencies without significant signal loss, making them essential for communication devices and advanced electronics. The demand for such materials reflects the broader trend toward miniaturization and improved signal integrity in electronic systems.

Another influential material is the development of flexible printed circuits, made possible by advancements in polymer technology. These circuits not only provide designers with greater flexibility in terms of space and form factor, but they also contribute to lighter, more durable electronic products. The use of advanced substrates, such as polyimide and PET, in flexible PCBs helps achieve the necessary performance while allowing for innovative designs. As the industry progresses, the incorporation of these materials will undoubtedly shape the future of PCB assembly processes, leading to smarter and more efficient electronic devices that cater to the ever-evolving market needs.

As we move towards 2025, automation is set to play a pivotal role in the PCB manufacturing sector. According to a report by market research firm IHS Markit, the global demand for automated assembly lines in electronics is projected to increase by 25% over the next three years. This shift is primarily driven by the need for higher production efficiency, reduced labor costs, and improved accuracy. Automation technologies, including robotics and artificial intelligence, are reshaping traditional PCB assembly processes, minimizing human error and increasing throughput.

Moreover, the integration of automation in PCB fabrication is not limited to the assembly line. Advancements in software analytics enable manufacturers to monitor production in real-time, optimizing operations and predicting maintenance needs before issues arise. A study by IPC – Association Connecting Electronics Industries suggests that manufacturers employing advanced automation techniques see a reduction in production costs by up to 30%. As these trends solidify by 2025, embracing automation will be essential for PCB manufacturers looking to remain competitive and responsive to the rapidly evolving technological landscape.

Sustainability is becoming a cornerstone in the production and design of printed circuit boards (PCBs), reflecting a shift towards environmentally-friendly practices. As the demand for electronic devices grows, the PCB industry is prioritizing sustainable materials and processes. This includes using materials that are less harmful to the environment, such as recyclable substrates and lead-free solder. Moreover, manufacturers are adopting closed-loop systems that minimize waste and maximize resource efficiency, ensuring that production aligns with eco-friendly principles.

In addition to materials, energy consumption during PCB fabrication and assembly is also being addressed. Companies are investing in energy-efficient machinery and optimizing production workflows to reduce their carbon footprint. Moreover, the implementation of renewable energy sources within manufacturing facilities supports a more sustainable approach. Designers are also increasingly considering the end-of-life recyclability of PCBs in their initial designs, creating products that can be easily disassembled and repurposed. This holistic approach to sustainability not only benefits the environment but also meets the growing consumer demand for greener technology solutions.

| Trend | Description | Impact on Sustainability | Estimated Adoption Year |

|---|---|---|---|

| Eco-Friendly Materials | Use of biodegradable and recyclable materials in PCB manufacturing. | Reduces waste and environmental footprint. | 2025 |

| Energy-Efficient Manufacturing | Implementation of energy-efficient processes in PCB fabrication. | Lowers carbon emissions associated with production. | 2025 |

| Water Conservation in Production | Techniques to minimize water usage in PCB manufacturing. | Promotes resource efficiency and sustainability. | 2024 |

| Design for Recycling | PCB designs that simplify the recycling process. | Encourages recycling of electronic waste. | 2025 |

| Circular Economy Practices | Creating systems for reusing materials used in PCBs. | Reduces material waste and supports sustainable practices. | 2024 |

The PCB fabrication and assembly industry is poised for significant evolution by 2025, driven by market demands and technological advancements. As this sector adapts, the growing need for high-performance, lightweight, and cost-effective solutions will be at the forefront. Notably, the fiberglass fabric market is projected to reach USD 13.17 billion by 2029, reflecting a robust demand for materials that enhance the performance of printed circuit boards. This alignment with market forecasts underscores the critical role that material innovations will play in achieving efficiency in manufacturing processes.

Additionally, the impact of emerging technologies, such as Artificial Intelligence, cannot be overlooked. AI is revolutionizing traditional industries, including manufacturing, by streamlining operations and increasing productivity. As industries evolve, the adaptation to these technological trends will be essential for PCB manufacturers to remain competitive. These shifts highlight the necessity for companies to not only forecast market demands accurately but also integrate new technologies that enhance production capabilities, ensuring they meet the requirements of a rapidly changing landscape.